| Place of Origin: | Yancheng, Jiangsu |

| Brand Name: | Yuancheng |

| Model Number: | YC-1700 |

| Certification: |

| Minimum Order Quantity: | 1 |

| Price: | 4000$ |

| Packaging Details: | WOODEN CASE |

| Delivery Time: | within fifteen days |

| Payment Terms: | 30% deposit. 70% balance before shipping |

| Supply Ability: | Large capacity warehouses and supply capacity to meet your needs |

Quick Detail:

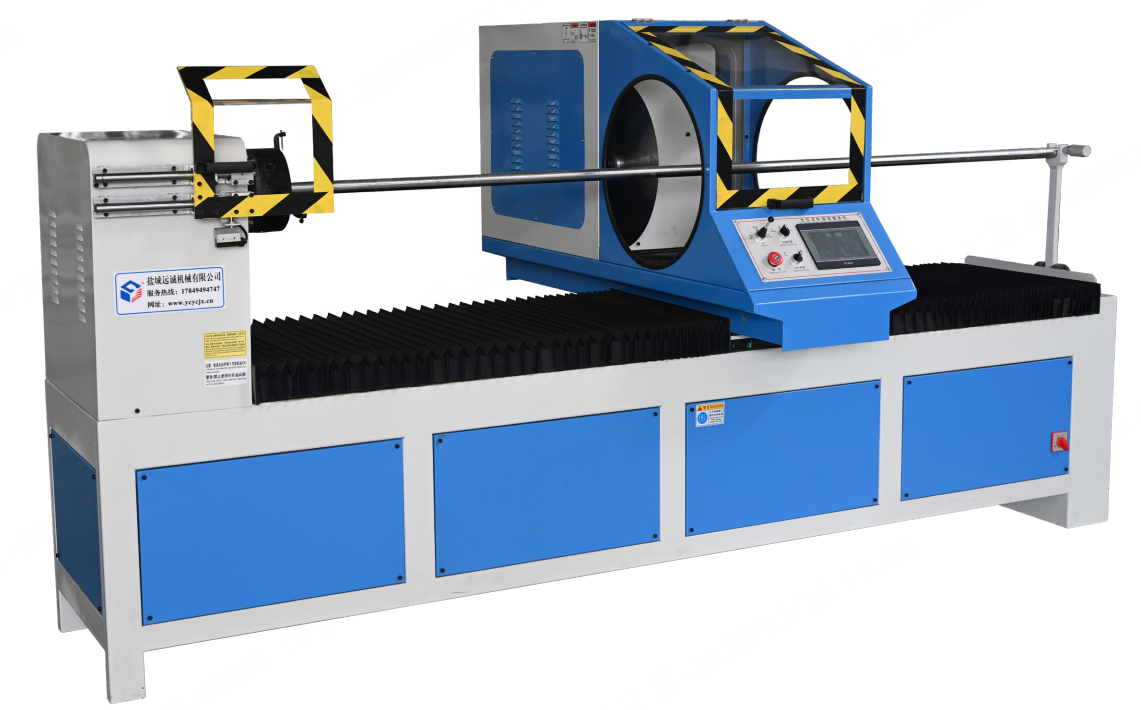

Sure, here is the information about the YC-1700 Dual Servo Automatic Cutting Machine in English:

1. **Different Names for the Product**:

This product can also be referred to as an "Automatic Cutting Machine", "Dual Servo Cutting Machine", or "Automatic Strapping Machine".

2. **Main Uses**:

This machine is primarily used for cutting various widths of straight strips, cross strips, and 45-degree diagonal strips of materials such as fabric, non-woven fabric, tents, umbrellas, foam, leather, reflective materials, plastic, paper, double-sided tape, acetate cloth, reinforcing tape, conductive cloth, copper foil, etc. It is an ideal choice for industries such as clothing, luggage, shoes and hats, clothing accessories, reflective material factories, tent factories, umbrella factories, electronic factories, etc.

3. **Core Specifications**:

- Fabric Width: 1.7 meters (2.05 meters and 2.4 meters are also available)

- Fabric Speed: 0-800 rpm

- Cutting Diameter: 300 mm (400 mm and 500 mm can also be customized)

- Motor Power: 0.75 kW

- Blade Motor Power: 1.5 kW

- Minimum Cutting Width: 2 mm

- Voltage: 380V/220V (optional)

- Dimensions: 2.7m x 1.5m x 1.7m

Description:

Here is a detailed description of the YC-1700 Dual Servo Automatic Cutting Machine in English:

**Technical Parameters**:

- Model: YC-1700

- Product Name: Dual Servo Automatic Cutting Machine

- Fabric Width: 1.7 meters (2.05 meters and 2.4 meters are also available)

- Fabric Speed: 0-800 rpm

- Cutting Diameter: 300 mm (400 mm and 500 mm can also be customized)

- Motor Power: 0.75 kW

- Blade Motor Power: 1.5 kW

- Minimum Cutting Width: 2 mm

- Voltage: 380V/220V (optional)

- Dimensions: 2.7m x 1.5m x 1.7m

**Applicable Scope**:

This machine is suitable for cutting various widths of straight strips, cross strips, and 45-degree diagonal strips of materials such as fabric, non-woven fabric, tents, umbrellas, foam, leather, reflective materials, plastic, paper, double-sided tape, acetate cloth, reinforcing tape, conductive cloth, copper foil, etc. It is an ideal choice for industries such as clothing, luggage, shoes and hats, clothing accessories, reflective material factories, tent factories, umbrella factories, electronic factories, etc.

**Equipment Features**:

1. The main shaft and circular knife use a stepless speed change system, which can control the high and low stepless speed and reverse cutting switch.

2. Imported PLC and imported high-precision stepping system control the cutting width and knife cutting system, with imported precision ball screw and slide rail displacement, high life, not easy to wear, making the cutting width accuracy reach 0.1mm.

3. The operation interface uses an LCD Chinese display screen. All operations only need one screen, can set four kinds of slitting widths and times at the same time, and display the actual cutting times, and have manual/automatic conversion function.

4. Equipped with a double-sided knife sharpening system, using diamond grinding wheel grinding, durable, not easy to heat, the blade is highly smooth after grinding, the service life is ten times that of ordinary white jade steel grinding wheel, the blade does not need to be disassembled, and can be sharpened.

5. Adopt quick release design, one step in place. Loading and unloading only requires one action.

6. The circuit adopts independent control systems, each line has a number, diagnosis and repair are simple and fast, and it is not easy to fail.

7. The fabric chuck is equipped with a safety guard, which does not hurt people.

8. The wire is protected by engineering plastic chains, the wire is not easy to break, and it is not easy to age.

This machine is designed with the user's needs and safety in mind, making it an efficient, precise, and user-friendly device.;

Applications:

Suitable for fabrics, non-woven fabrics, tents, umbrellas, foam, leather, reflective materials, plastics, paper, double-sided tape, acetic acid cloth, reinforcement tape, conductive cloth, copper foil and other materials with various widths of straight strips, horizontal strips, and 45 degree diagonal strips for rolling and cutting. It is an ideal choice for industries such as clothing, luggage, shoes and hats, clothing accessories, reflective material factories, tent factories, umbrella factories, electronics factories, etc.

Specifications:

| technical parameter | |

| Model | YC-1700 |

| Product name: | Dual servo fully automatic cutting and bundling machine |

| Fabric width | 1.7 meters (with options of 2.05 meters and 2.4 meters) |

| Fabric speed: | 0-800 (revolutions per minute) |

| Cutting cloth diameter | 300mm, can also be customized with 400mm or 500mm |

Competitive Advantage:

1. The spindle and circular cutter use a continuously variable speed system, which can achieve high and low speed control and forward/reverse switching control.

2. Using imported PLC and imported high-precision stepper system to control the cutting width and advance/backward cutting system, combined with imported precision ball screw and slide rail displacement, it has a long service life and is not easy to wear, making the cutting width accuracy reach 0.1mm. The narrow cutting width is parallel and fast during feed cutting, and the speed is stepless speed regulation. The paper tube is easy to cut, achieving high-precision and fast cutting of high-quality products.

3. The operation interface adopts an LCD Chinese display screen, which only requires one screen for all operations. It can simultaneously set four cutting widths and times, and display the actual cutting times. It is also equipped with manual/automatic switching function

4. Equipped with a double-sided grinding system and using diamond grinding wheels for grinding, it is durable and not easy to generate heat. The blade has a high smoothness after grinding, and its service life is ten times that of ordinary white jade grinding wheels. The blade can be ground without disassembly. The blade remains sharp for a long time to achieve good cutting quality, and is equipped with an automatic vacuum device to keep the fabric and track clean.

5. Adopting a fast feeding design, it can be achieved in one step. Loading and unloading can be completed with just one action.

6. The circuit adopts various independent control systems, and each line is labeled. Diagnosis and maintenance are simple and fast, and faults are not easy to occur.

7. The cloth clamp is equipped with a safety cover, which does not harm people.

8. The wires are equipped with engineering plastic chains for protection, making them less prone to breakage and aging.

9. Can effectively prevent dust and protect the machine

Copyright © Yancheng Yuancheng Machinery Co., Ltd. All Rights Reserved - Privacy Policy - Blog